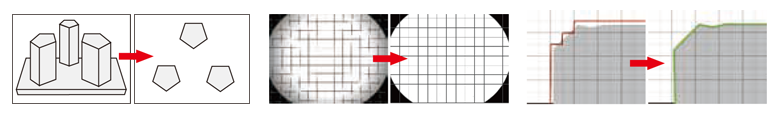

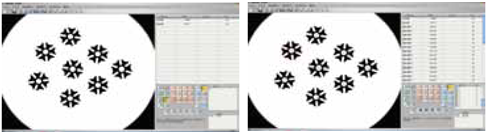

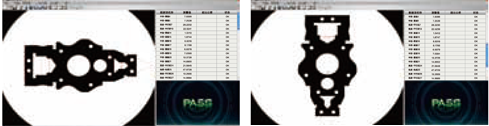

This system is an independently researched and developed optical system and employs a high-efficiency precision image processing calculation method. Its high-resolution CCD and telecentric lens can capture any image, and measure necessary dimensions of mechanical parts precisely by performing image processing analysis by using software. This system has opened a new era for quickly measuring an image, instead of the existing measurement methods. It can perform any complicated measurement easily and quickly with just one touch.

The all-in-one measurement system will help customers to make more profits by enhancing efficiency of a work process and reducing cost. The system has a stable body structure, and helps users with comfortable operation regardless of a shape or color of a sample.

-

Measurement precision± 2 ㎛

-

Repeatability precision± 1 ㎛

-

A large area95mm x 80mm

-

High-resolutionCCD with 5 million pixels